Zhong Jiu metal products Co., Ltd.

Contacts:Mr. Jiang

Telephone:13806222568

0512-58580988

Mailbox:sales@cn86.cn

Website:www.zjg-zj.com

Address:Zhangjiagang city yangshe town

Zip code:215600

1 check the wear resistant rubber ring on the rope wheel. The wear of the rubber ring is perpendicular to the rope saw wire rope, which is the normal ideal wear. But often happen to the side of the grinding, wear to a certain extent, the rubber ring should be turned 180 degrees in order to wear the other side. When the wear to a certain degree to be replaced.

If the side wear serious, sometimes worn rim, in this case, not only to change the rubber ring, may also change the rope wheel. So should always pay attention to check.

2 weekly should check the oil level of a gearbox and reducer, need to refuel, to ensure lubrication.

3 rope saw the first running time up to 50 hours to change, after 400 hours of operation of oil a. Different grades of oil should be used in different seasons. And the driving device, the return line storage device, the longitudinal tensioning mechanism, the work column and other parts of the rope round, at least once every 10 days or so lubrication.

4 keep the track of the longitudinal tensioning mechanism clean, clear sand and obstacles, to ensure the smooth movement of the tension car. Www.stone595.com

5 attention to the driving device running in the process of a large vibration, to check some of the connection parts of the fastener.

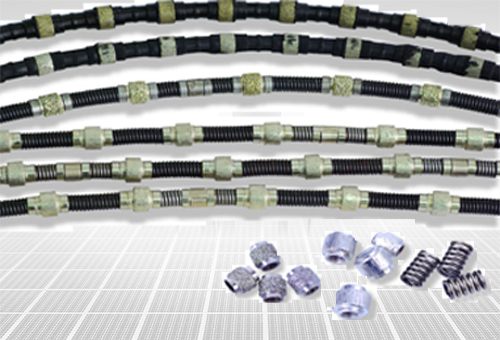

To confirm the direction of the rope saw before the installation of the rope saw must ensure that the direction of the arrow on the wire saw is in line with the sawing direction. Some use after the rope, can not see the rubber on the direction of the arrow, you can according to the direction of diamond particles on a string of beads to identify the direction of the wire saw. From the surface to be cut into the drilled hole in wire saw. Note: vertical cutting, wire saw, must enter from the direction along the horizontal hole, passes through the vertical hole. The cutting plane is determined according to the actual position of the wire saw through direction, from old to new, the direction to be consistent. If the anti wear and use, the wire saw will probably not. Don't mix the new rope with the old rope to use, it will cause a lot of waste, but also caused the accident of the card rope and rope broken. Wire saw in connection must use special rope saw connector (gifts), remember before connecting to the rope saw pre rotated a certain number of laps and rotating counter clockwise, number of rotations for 1 ~ 3 (circle / M), according to the extent of wire saw was the use, new rope can lap 1 / M, the rope used to according to severity of use, gradually increasing twisting rounds, a maximum of not more than three laps / m, too much will cause wire rope fatigue caused by beads series, wire saw will not be. Hydraulic crimping pliers will have been rotating circle number of the wire saw with special joints connected to surround the rope saw machine to drive the flywheel on.